- Products

- Production examples

Koga Machine and Robotics Co., Ltd., is a manufacturer of industrial automation equipment including tapping machines, cutting machines,

robotic systems and press processing machines.

We continue to develop and manufacture a wide variety of products to support our customers' production activities around the world.

Introducing Koga's products. You can view our product lineup and specifications.

Production examples of our products as used by customers in various industries.

Company profile of Koga Machine and Robotic Co., Ltd. from here.

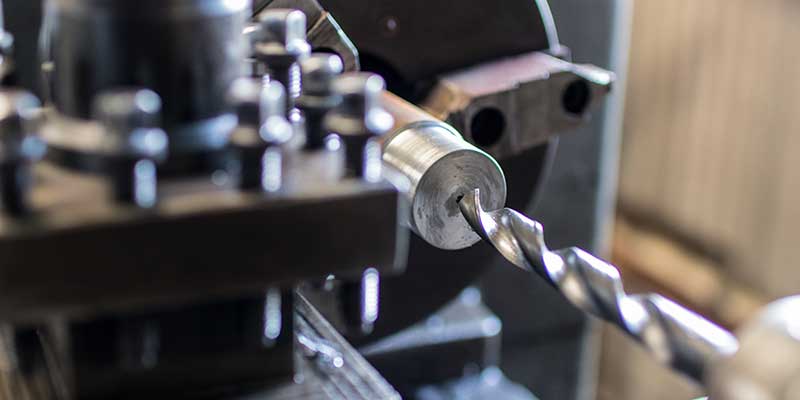

Micro tap unit

This is an introduction to our in house manufactured and designed "Micro tap series," recommended by Koga Machine and Robotics with confidence. Compact in size, but enormous in flexibility. This machine can perform all the aspects of tapping even while other operations are taking place on the workpiece. This machine can tap holes during die pressing operations or tap on its own. It can even tap holes while the workpiece is undergoing other operations in a custom made Koga machine or in your existing machinery. Increase efficiency and cut production time by combining taping with other manufacturing steps. If you are thinking of shortening the tapping process and improving workability, please don’t miss it.

Micro tap unit MT-6 is designed using a dynamic structure that ensures accuracy by correcting deviation of the pilot hole and negating the vibrations of the material. Each unit has a driver which can be independently set. It is available connected directly to the motor or on a flexible shaft . The flex shaft option can allow you to mount the unit in places that will be exposed to cutting fluids or large amounts of chips.

| Tap size | M3~M6 |

|---|---|

| Pitch Size | 0.5、0.6、0.7、0.8、1.0 |

| Tap stroke | Max 25mm |

| Feed Method | Master screw method |

| Lubrica on method | Grease inclusion |

This tap can be used in dedicated jigs and units for taping alone or it can be used in a die cutting press. This unit is only available with the flex shaft.

| Tap size | M1.4~M3 |

|---|---|

| Pitch Size | 0.3、0.35、0.4、0.45 |

| Tap stroke | Max 20mm |

| Feed Method | Master screw method |

| Lubrica on method | Grease inclusion |

Machining start position, stroke and speed are all precisely controlled by a servo motor. The drive unit resets to it’s home position by way of a mechanical stop for consistent depth of tapping.

Users can set the tap stroke and RPM on the control unit box. The control box can interface with other machines by way of a digital start and stop signals. This allows the unit to coordinate it’s tapping with other assembly steps.

| Program Box PB-1 |

L40 x W100 x H160mm |

|---|---|

| Control Box CB-2 (For MT-2) |

L225 x W295 x H270mm |

| Control Box CB-4 (For MT-6) |

L225 x W295 x H270mm |